Aws Cwi Things To Know Before You Buy

Table of ContentsThe Only Guide for Aws CwiExcitement About Aws CwiSome Ideas on Aws Cwi You Need To KnowNot known Facts About Aws CwiAws Cwi Fundamentals Explained

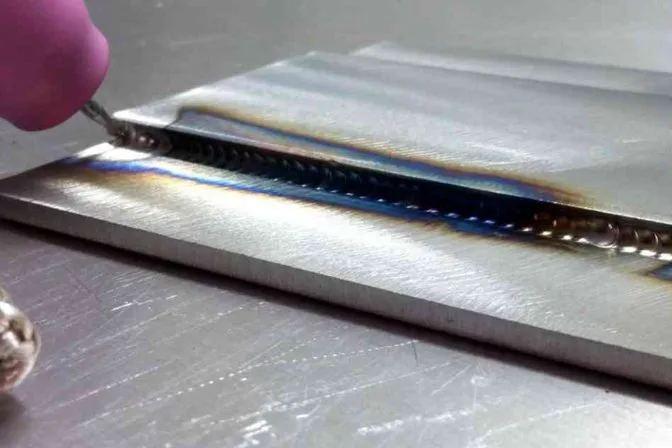

Third-party quality assurance examination of steel fabrication facilities on welding examination, along with assessment of bolting and paint of structural steel. KTA's steel inspectors give High quality Control (QC) examiners to supplement producer's/ contractor's internal QC team and on tasks that mandate keeping the services of a qualified inspector (e.g., CWI) employed by an independent assessment firm.Inspectors carry out visual inspections of material for uniformity with the approved specifications, strategies and codes, as well as verification of Licensed Product Examination Records (CMTR) for products used. Materials and components are observed at key factors along the manufacturing procedure in both steel mills and steel manufacture shops. KTA's certified welding examiners additionally witness welder and welding treatment credentials examinations as relevant to the range of the task.

Steel manufacture inspection solutions additionally regularly consist of carrying out non-destructive testing (NDT), additionally recognized as non-destructive evaluation (NDE), consisting of Magnetic Particle Testing (MT), Ultrasonic Testing (UT) and Liquid Penetrant Checking (PT). KTA's evaluation solutions include covering examinations covering surface area preparation, painting, galvanizing, and metalizing.

KTA's ideology is to respond rapidly to clients' demands, match the appropriate examiner to the job, and offer the requisite paperwork. KTA has the assistance workers to offer technical consulting to the area workers and to the client. KTA has experts available to get in touch with on welding, NDT and coverings.

FST Technical Provider is your global companion in the Semiconductor and Pharmaceutical Industries! Our settings consist of advantages such as medical, oral, vision, life, 401(k) with company match, PTO, paid vacations. Come sign up with a remarkable group in an amazing, quick paced, and ever-growing market! We are looking for a CWI's and/or NDT Level II certified Welding Inspectors from around the Lithia Springs, GA location! Local area candidates are encouraged to apply however this position is open to vacationers with mobilization and monthly daily for those living outside the area.

The Only Guide to Aws Cwi

Suitable candidate will certainly have high pureness piping examination experience. CWI's and NDT Degree II's extremely motivated to apply.

Pro QC's third-party welding assessment solutions consist of: Record Evaluation Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Screening (NDT) Others Our welding assessment records are provided within 1 day and document all inspection factors appropriate to high quality, consisting of all determined weld blemishes and electronic images (Weld Inspector) (https://www.pearltrees.com/awscw1w3lding#item647532147). Pro QC's team of assessors supplies third-party welding inspections around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the United Kingdom, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the United States, Mexico, copyright, Brazil, Peru, and a lot more countries

Evaluation of the welding work is important for correct quality When your business is dealing with significant tasks with demands for 3rd party independent welding evaluation, we give outstanding welding witness assessment solutions to validate that welding has been carried out according to the majority of used welding requirements and specs. AQSS carries out welding examination solutions for customers from a variety of industries.

Rumored Buzz on Aws Cwi

Not adhering to appropriately qualified welding treatments often results in a weld of below average high quality, which can boost the construction's chance of failure under intended solution problems. By inspecting for flaws, our examiners can assist clients ensure that their welds satisfy appropriate criteria of quality control (Weld Inspector). Weld inspections are conducted for several reasons, the most usual of which is to establish whether the weld is of suitable high quality for its desired application

Our welding assessors have the required certifications with years of experience with inspection and are familiar with a lot of applied welding standards and specs. AQSS has CWI licensed examiners.

Excitement About Aws Cwi

Commonly, our examiners are examining for splits, pits, surface area pores, undercut, underfill, missed joints, and various other elements of the weld.

Examples can additionally be taken at intervals throughout the go to this web-site production process or at the end of the run. Damaging testing examples are precisely reduced, machined, ground, and polished to a mirror-like surface. An acid etch is then put on visually draw out the weld, and the sample is after that evaluated under a microscope.